for Hydrogen

Available Now, Contact Us To Learn More!

Harness the Power of Sustainable Fuel

The push to transition to hydrogen energy sources is growing. However, hydrogen flame fits through smaller gaps than methane, making it challenging to provide flame arresting. That's where the Sigma Hydrogen Explosion Pressure Relief Valve comes in.

Our patented technology is designed to withstand the demands of hydrogen service. The Sigma Hydrogen Explosion Pressure Relief Valve is tested for hydrogen applications, including reciprocating compression.

FAQ's

Hydrogen is a combustible gas. When a cloud of gas is ignited, the rapid combustion of hydrogen can create overpressure and result in an explosion. Even with the risk of explosion, hydrogen internal combustion engines are expected to play a significant role in decarbonizing various shipping industries.

Hydrogen flames fit through small gaps, making it difficult to provide flame arresting. When compressing highly combustible fuels, the safety of your people, process, and equipment is crucial.

While Penn-Troy and its BICERA Valve division cannot prevent a hydrogen explosion, we make the best hydrogen explosion pressure relief valves to contain the dangers and damage associated with crankcase pressure.

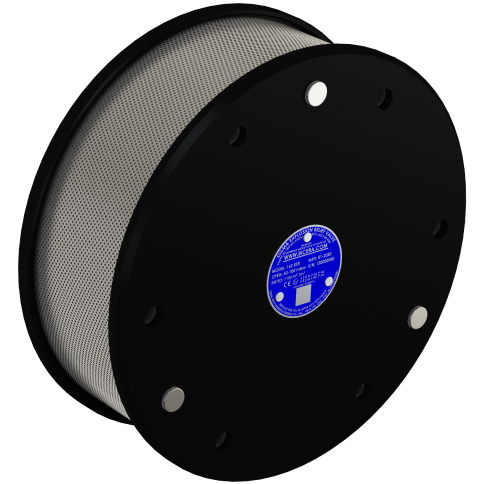

Hydrogen Crankcase Explosion Relief Valves have two functions: they relieve crankcase pressure and prevent flames from escaping the crankcase. Sigma for Hydrogen Crankcase Explosion Relief Valves from BICERA are designed to protect more while using less material and align perfectly with the mounting pattern of your existing equipment.

The Sigma Valve has a spring-loaded plate that reseals the valve after an explosion to stop oxygen from getting sucked back into the engine and causing a secondary explosion. This feature is also critical for applications where shutting down machinery for maintenance is not always possible.

To ensure proper maintenance and operation of hydrogen pressure relief valves:

- Inspect regularly to make sure the valve is clean and unobstructed from debris

- Exercise valve plate annually

- Keep O-ring lubricated with dielectric grease to prevent sticking

- Keep records of maintenance

- Provide training for maintenance engineers

- Consider environmental factors